Spray Automation and Cotrol Systems

System Over view

If you are looking to integrate a your spray booth system into your new project or existing facility, we provide you independent

and expert solutions by our in-depth knowledge and experience we

can assist in selecting the best system for your needs, providing detailed drawings showing how this can be fully integrated into your facility.

Core Technology

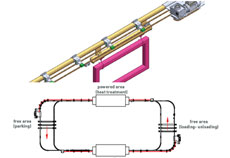

PLC and SCADA system design up to 3 layer of enterprises

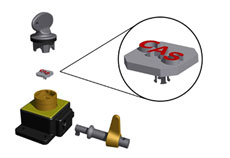

RFID TAG designed for Paint line

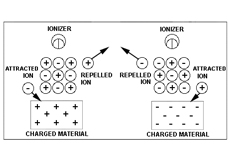

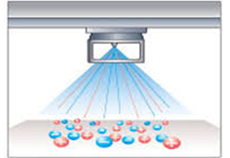

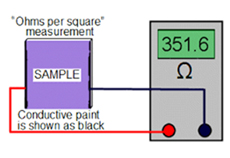

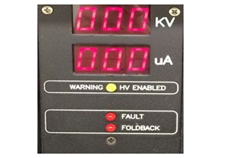

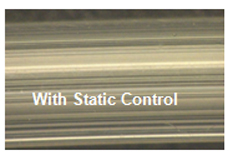

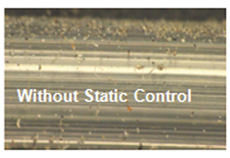

Electrostatic systems for status and High Voltage systems

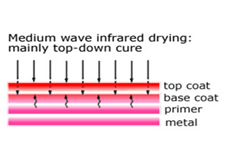

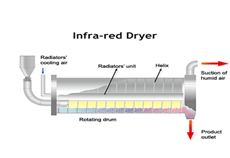

IR heating and Flame proof lighting auto control design

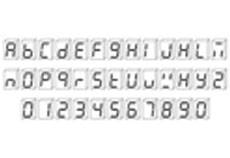

All size alphanumeric display control system

Digital control with ring main and Ethernet ,Sercos network tropology

Area of application

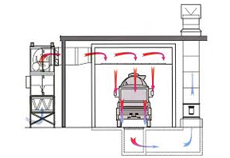

Paint Booth, Spray Equipment, Line tracking and monitoring ,Conveyor transfer ,Earthling and testing ,Illumination control, operation and safety control Power backup and heating solution, Electrostatic solution

Our Solutions for Spray Automation and Control

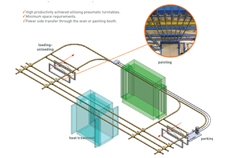

Floor and overhead conveyor Integration

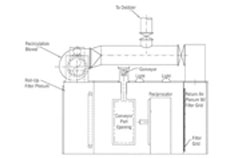

Automatic Paint shop Lighting

Auto door for booth Opening

Spray Booth SMART control on desk

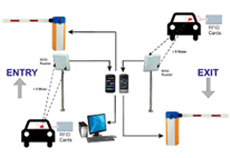

RFID and tracking system

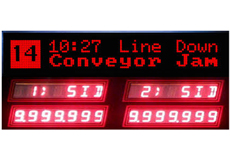

Type & color ID, Line Error display unit

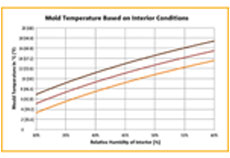

Temperature and Humidity Control

Safety interlock systems

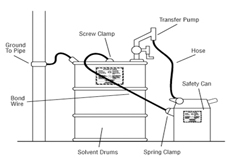

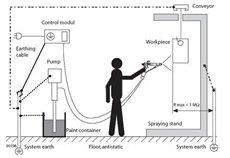

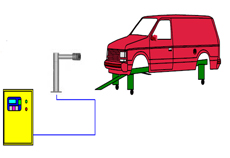

Earthling and grounding systems

Static Charge removal systems

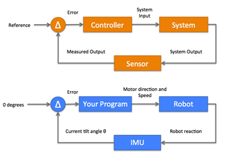

Sensor feedback control systems

Heating and filtration solution

Power Backup systems for robots

Paint Line Part transfer conveyor

Auto door clousre and opener for booth

Automatic floor lighting for paint shop

Smart Booth Control desk

RFID and Line Tracking Systems

Type and Colour ID display system

Temperature and Humidity Control

Safety interlock systems

Earthling and grounding systems

Static Charge removal systems

Sensor feedback control systems

Paint Drying & Power backup system

Remote Support

Remote Support Company Brochure

Company Brochure Request For Quote

Request For Quote Publication

Publication Career With Us

Career With Us Customer Voice

Customer Voice