Production Support

Production Support

The Production Support Services is to bridge the process and procedural gaps between production management and qualified resources for defined operational areas, Our production support service strategy is to provide best service with the goal of minimizing potential failure through active involvement to achieve daily production target.

As we know today's manufacturing environment is becoming more complex and knowledge oriented. moreover, due to the complicated nature of the manufacturing environment, it is becoming increasingly difficult to resolve problems quickly. Our support service ensures that our systems and equipment always run efficiently , With our best services customer will be get benefited to achieve daily production target and improve utilization factor of equipment

Based on many years of extensive experience globally in paint application industry, customer support and technical field ,Our Services is pleased to offer its individual services or complete service packages as per customer requirements for plant operation . We work hard to maintain the productivity of our customers' facilities by resolving their problems quickly and accurately.

Service Category :

Full Operation

Production Planning

Annual Maintenance Contract

Remote Diagnostic

Emergency Breakdown

Line Audit and Improvement

Preventive Maintenance/Health Checkup

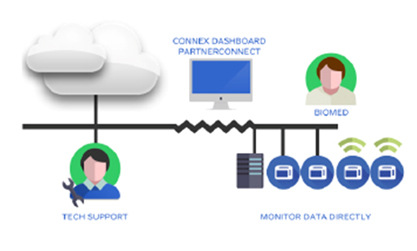

Remote Diagnostic

With our remote service agreement customer will be able to get "ON Demand" service support with the help of latest remote monitoring software and document, The remote setup will be done for communication on customer end as well in our office for a robotic paint line.

Attend equipment break down and provide instant emergency support.

Real time remote diagnostic system to attend the break down

Easy to do why-why analysis, Poka-Yoke and maintain breakdown history

Eliminate resource dependability

Small Modification instantly

Hot line support

Minimize production loss

Help to improve equipment operation

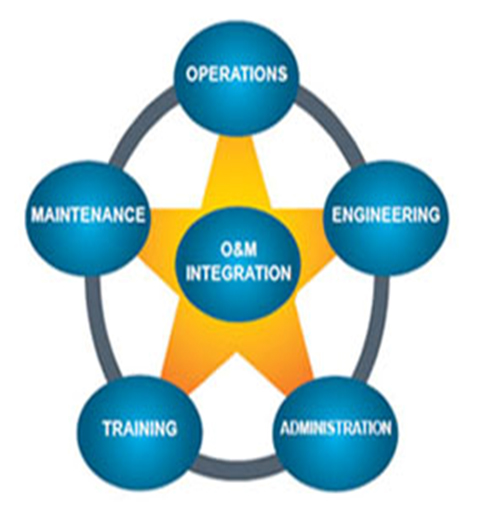

Full Operation

24/7 support for operation and Maintenance

We can take complete responsibility for line operation including production and maintenance on per part rate basis for a robotic paint line

Achieve smooth operation of production line

Achieve daily target production

Process Parameters Optimization for maintaining the desired product quality

Co-ordination between m a n a g e m e n t a n d ope ration t e a m

Performance monitoring & evaluation

Advice on improvement /standardization

Quality Improvement

Annual Maintenance Contract

We can take annual maintenance contract for entire robotic paint line on defined number of visits for planned and preventive maintenance, emergency breakdown support.

Achieve smooth operation of production line

Support to achieve smooth running of robots

Support to achieve desired Uptime of Robots and sub equipment's

Spare Parts & wear Parts identification & service

Co-ordination between m a n a g e m e n t a n d ope ration t e a m

Need based service support like training, presentations, consultation

Awareness on recent developments in Robots Technology

Support for performance monitoring & evaluation

Advice on improvement /standardization

Line Audit and improvement

As a external audit we can improve paint line efficiency with our expertise and knowledge in the spray painting field.

Support to achieve desired material cost

Minimize the rework

Eliminate Frequent failure if equipment

New design concept

Line retrofitting

New equipment integration

Problem reporting structure development

Support for performance monitoring & evaluation,

Advice on improvement /standardization